Civil, Structural Engineering and Building

Cambridge Area Resignalling – GRIP 6-8 Civils Works

DATE: Apr 2026

LOCATION: Cambridge

Global Rail Construction Limited (GRCL) were awarded a long-term programme of GRIP 6-8 railway civil engineering works, on behalf of valued client and Cambridge Resignalling Principal Contractor and Designer, Alstom. This sub-contract was secured by our UK team, following previous successful delivery of both GRIP 4 Surveys and GRIP 5 Advanced Civils Works.

Cambridge Resignalling is a condition led renewal, where a significant number of level crossings will be either renewed or modified as part of the project. The scope covers the area controlled by Cambridge signal box.

The delivery programme covers 4-key commissioning stages – Stage 1 Commissioning in December 2024, Stage 2 Commissioning May 2025, Croxton Stage October 2025 and Stage 3 Commissioning Easter 2026, and requires GRCL to interface with Alstom’s Lead Engineers and provide inputs into other discipline requirements/deliverables.

GRCL provides competent management and staff to ensure that the works meet the required Network Rail standards and the expected level of quality, in order to assist Alstom with production and verification of the scheme, to enable satisfactory and timely sign off of the Engineering Completion Certificates for all stages of the works.

Feltham Resignalling Project Phases 3-4 Advanced Civils

DATE: Sep 2022

LOCATION: Feltham to Wokingham

Principal Contractor Global Rail Construction Limited (GRCL), has completed Feltham Resignalling’s largest civil engineering programme of works, on behalf of Network Rail (NR) Southern Region Capital Delivery.

In October 2020, Global Rail Construction commenced works as the Principal Contractor for the Design and Construction (D&C) of the Advanced Civil Engineering scope of works for Feltham Resignalling Project Phases 3&4. These phases form part of a major Resignalling project to renew life expired signalling, telecoms, and electrical assets for Network Rail, comprising the renewal of 538 Signalling Equivalent Units (SEUs) over 80 miles of railway lines, alongside the introduction of a brand-new signalling system from Atkins – Elix.

Design activities commenced at pace and site works were meticulously planned as part of a compelling tender methodology and approach utilising weekdays and nights, Saturday nights and several 28 and 52-hour railway possessions during a most challenging project timeframe.

The construction works were further extended to September 2022 to include several additional location case hardstanding’s, PSP compounds, new signal installations, new cable duct routes to existing station platforms and the installation of various new troughing routes – all effortlessly absorbed by GRCL’s in-house D&C team.

Having a railway design and build team, including dedicated project and site management across the civil and structural engineering scope, familiarity with the scheme, having delivered several previous phases and having delivered time pressurised resignalling schemes across Network Rail infrastructure, allowed Global Rail Construction Limited to provide the necessary turnkey solution and complete the project to meet Network Rail’s requirements

Thameslink Project

DATE: Jul 2021

LOCATION: London Bridge

Global Rail Construction Limited were among a team of specialist rail contractors working in a highly coordinated manner to deliver these important upgrades for Network Rail. The in-house team of multi-disciplinary experts from Global, have worked almost entirely within a live, operational environment, interfacing daily with equipment that is switched on, in a wholly compliant manner.

The specialist discipline support services undertaken by Global Rail Construction Limited cover the entire end-to-end design and build scope of the Signalling, E&P and Ancillary Civil Engineering programme.

Power Supply Upgrade – West Ham, London

DATE: Jul 2014

LOCATION: West Ham, London

Global Rail Construction Ltd (GRCL) was awarded a £3m design and construct contract associated with eight existing and one totally new substation at West Ham on the Metropolitan & District Line. Having worked closely with the client at tender stage in support of their bid to LUL, GRCL fully project managed all aspects of the design and construction of the civil and building elements of the work. The existing substations were: Campbell Road, East Ham, Heathway, Hornchurch, Plaistow and Upminster Bridge.

In general, works at these substations were to strengthen and alter the existing buildings and structures to allow the positioning of new transformers, switchgear, cables and ancillary equipment or provide new bases, structures and building extensions to support and house the same.

Sunningdale Level Crossing Renewal

DATE: Nov 2021

LOCATION: Sunningdale, Feltham Resignalling Scheme

Global Rail Construction Limited (GRCL) was awarded a multi-disciplinary contract on behalf of Atkins Global for the Civil and S&T installation works for a new level crossing at Sunningdale, which falls within Feltham Resignalling Phase 2.

The overall Feltham Resignalling Project covers the renewal of all signalling assets. Its area is covered by seven scheme plans, with delivery broken down into six separate Phases that align approximately to the Signalling Scheme Plan boundaries, Feltham ASC Signallers panels and Wokingham Signal Box.

Within the early advanced scope of Phase 2 was Sunningdale MCB-CCTV, which is subject to a full level crossing renewal – due for completion in November 2021. The scope encompasses life extension works with addition of barrier repositioning and narrowing of carriageway.

Clacton Resignalling Scheme

DATE: May 2021

LOCATION: Clacton-on-Sea

Global Rail Construction Limited (GRCL), has successfully completed a railway civil engineering design and build programme of works on behalf of partner Atkins Global, to support the upgrade the signalling systems in the Clacton-on-Sea area.

The Clacton Resignalling Projects’ principle driver was the asset condition of the interlocking and associated track infrastructure at the throat of Clacton-on-Sea station.

Much of the signalling in the area dated back to 1958 and utilised a lever frame dating from 1891. There was a mixture of semaphore and colour-light signals, controlled by a mechanical/electro- mechanical lever frame. There was also a mechanical ground frame at Clacton Station. The existing signalling equipment has been previously subject of life extension works in both 1996 and 2004.

Many components were obsolete and only available on a repair and return basis. Most of the existing location cases had considerable corrosion. The signalling uses some single-cut circuits which are the subject of ORR concern. Searchlight signals were installed on this line, with known Wrong Side Failure (WSF) modes. P-Style relays in the lower portion of the box were recognised as susceptible to sliver migration. So, these works, will minimise maintenance and reduce whole life costs.

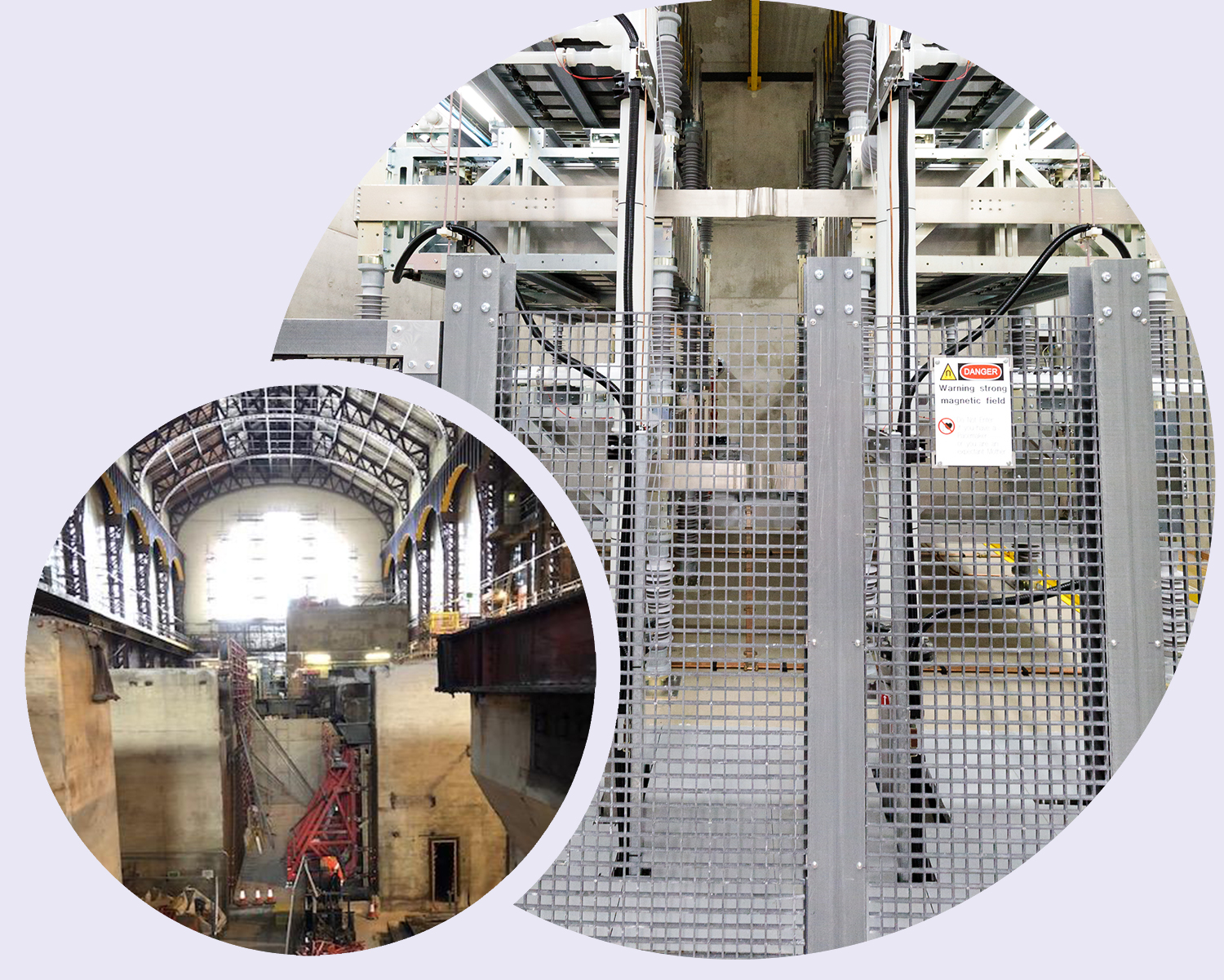

Greenwich SVC – Enclosure Design and Build

DATE: Oct 2018

LOCATION: Greenwich Generating Station

Global Rail Construction Limited (GRCL) has successfully completed the Design and Build of a Static VAR Compensator (SVC) Enclosure at Greenwich Generating Station. Under Power Upgrades Package 5C, Siemens, as Principal Contractor, appointed GRCL to deliver the project, to house the new SVC within a disused turbine hall.

Access to the substation was via the Old Woolwich Road, which was challenging. An internal substation access road was used for all construction logistics and deliveries with minimum disruption caused to the local residents.

Whilst on site, GRCL were awarded a variation to provide further civils installation works associated with the extension to the existing 22kV Switch room located on the 1st Floor of the Sub-Station. These works included the demolition of the existing wall, strengthening of the floor using steel support and concrete screed, blockwork walls, self-levelling screed, door installation and plinth foundations.

Feltham Resignalling Project Phase 1

DATE: Apr 2019

LOCATION: New Malden to Richmond and Whitton via Strawberry Hill - Feltham, Middlesex

Global Rail Construction Ltd (GRCL) delivered a compelling tender to Network Rail Infrastructure Projects (NR) and in early 2017, were awarded the Principal Contractors role for the Design and Construction of the full civil engineering scope of works for the Feltham Resignalling Project Phase 1.

This phase of works forms part of a major Re-Signalling project to renew life expired signalling, telecoms and power assets for Network Rail, comprising the renewal of 538 Signalling Equivalent Units (SEUs).

The geographical work-scope, which covers over 80 miles of railway lines also includes, for the first time, the introduction a brand new signalling system from Atkins – Elix.

Works were planned during mid-week days and nights, Saturday nights and a number of 28/52-hour railway possessions between weekend 20 – 2017 and weekend 12 – 2018.

The works were further extended to April 2019 by Network Rail during the course of the contract, whereby a number of Location Case concrete hardstandings were constructed; a number of PSP compounds were designed and constructed, 52 new signals were supplied, delivered and erected; new cable duct routes were added to a number of existing station platforms; and the installation of various new trough routes were completed including their associated design over bridge locations.

Having a multi-disciplinary workforce including rail, civil and structural installation expertise, along with in-house project management, and having previously delivered time-pressurised re-signalling schemes, allowed Global Rail Construction to provide the necessary delivery solution and works have been fully completed to meet the client’s requirements.

Feltham Resignalling Project Phase 0

DATE: Jan 2016

LOCATION: Shepperton Branch Line, Feltham, Middlesex

Following previous successful contracts with Kier, Global Rail Construction Ltd (GRCL) again delivered a compelling tender and, in early 2016, was awarded the civil engineering scope of works for the Feltham Resignalling Project Phase 0 (Shepperton Branch).

The major resignalling project to renew life expired signalling, telecoms and power assets on behalf of railway systems giant Atkins, comprised the renewal of 538 Signalling Equivalent Units (SEUs).

The geographical work-scope, which covers over 80 miles of railway lines also included, for the first time, the introduction of Atkins brand new signalling system – Elix.

Works were planned during mid-week days and nights, Saturday nights and four 28-hour railway possessions between weeks 48 and 14, leading up to a 15-day blockade commencing in Week 16, between 16th and 31st July 2016.

Having a multi-disciplinary workforce including rail, civil and structural installation expertise, along with in-house project management, and having previously delivered time-pressurised re-signalling schemes, allowed Global Rail Construction to provide a delivery solution, one which the client readily accepted.

East Notts Modular Resignalling

DATE: Nov 2016

LOCATION: Nottingham to Grantham and Nottingham to Newark Lines

In April 2014, UK rail contractor Global Rail Construction Limited (GRCL). fought off stiff competition to be awarded the design and construction of the civil engineering scope of works (Grip 5-8), for the East Notts Modular Resignalling scheme on behalf of Alstom.

The remitted signalling renewals on Network Rail’s East Midlands Route, consisted of the replacement of life expired mechanical signalling equipment, with Alstom’s state of the art modular signalling concept.

This flagship project involved the use of Alstom’s latest obstacle detection (OD) technology at 9 separate level crossing sites, on both the Nottingham to Grantham and the Nottingham to Newark lines.

The project was to be completed whilst adhering with two critical project milestones commissioning dates in March 2015 and November 2015, culminating in final test, handback and completion in November 2016.

The project was also cutting edge in its safe working processes, as it also became the first project in the UK to implement NR//L2/OHS/133 – Network Rail’s brand new Code of Practice for Planning and Delivering Safe Work.

Global Rail Construction self delivered much of the work scope using their in-house civil and structural engineering teams.

Selby Swing Bridge

DATE: Dec 2012

LOCATION: Selby

Global Rail Construction were selected by Siemens as design and build civil engineering contractor for a Horizontal Directional Drill (HDD) that was required to cross under a Grade 2 listed building, the Great River Ouse, Ouse Road and the East Coast Mainline railway in the heart of Selby town centre.

Utilising their in-house multi-disciplinary design team, Global Rail Construction were able to offer Siemens a complete design and build solution.

The civil engineering works, which formed part of the Selby Rail Swing Bridge Signalling Interlocking Renewal being undertaken by signalling product specialist Siemens, were being specifically undertaken to renew the existing electricity cables, which had been installed in 1956 and were located under the river.

The project consisted of the replacement of the swing bridge cabin signalling interlocking onto a new interlocking building, incorporating new lineside equipment from locations 128, 129, 130 and 131, which also required cables to traverse into the river at this location. The conventional approach of simply running the signalling cable across the bridge was not appropriate, as one 40m span of the swing bridge – which was built in circa 1900 – allowed river traffic to pass. Hence, Global Rail Construction designed a suitable ducted solution to carry telecommunication, signalling and power cables on behalf of their client.

Cambridge Area Resignalling – GRIP 6-8 Civils Works

Feltham Resignalling Project Phases 3-4 Advanced Civils

Thameslink Project

Power Supply Upgrade – West Ham, London

Sunningdale Level Crossing Renewal

Clacton Resignalling Scheme

Greenwich SVC – Enclosure Design and Build

Feltham Resignalling Project Phase 1

Feltham Resignalling Project Phase 0

East Notts Modular Resignalling